How to optimize the sensor and measurement and control system of the electronic tensile testing machine?

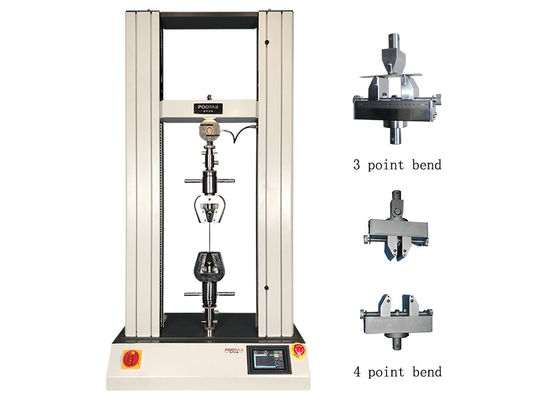

The electronic tensile testing machine is a mechanical testing machine used for static load, tension, compression, bending, shear, peeling and other mechanical properties of various materials. It is suitable for plastic sheets, pipes, profiles, and plastics. The testing of various physical and mechanical properties of materials such as films, rubber, wires and cables is for material development and is an indispensable testing equipment for physical testing, teaching research, and quality control.

Optimization of the sensor and measurement and control system of the electronic tensile testing machine:

The quality of the force sensor of the electronic tensile testing machine determines the accuracy and stability of the testing machine. At present, the sensor for the tensile machine on the market generally uses the S-type sensor for small force values, and the spoke-type sensor for the large force values. The internal sensor Generally, it is a resistance strain gauge type. If the accuracy of the strain gauge is not high, or the anti-aging ability of the glue used to fix the strain gauge is not good, or the material of the sensor is not good, it will affect the accuracy and service life of the sensor. The imported sensor has high accuracy, good linearity, and very stable performance, which will not change for decades.

At present, most of the measurement and control systems of tensile testing machines on the market are controlled by 8-bit single-chip microcomputers, which have a low sampling rate and poor anti-interference ability. In addition, if the number of bits of the AD converter is low, the resolution is also low. Then the measurement will not be accurate. The measurement and control system adopts a controller developed by advanced 32-bit ARM technology, which makes the program run more stable and the system more stable. The sampling rate can reach 200 times per second, and the addition of a 24-bit high-precision, low-noise and high-speed AD converter makes the entire measurement and control system more accurate and stable to control the entire test process, so that the entire test process can reach constant force Value control, constant displacement control, constant deformation control, low frequency fatigue control, and program arbitrary control.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!