High And Low Temperature Tensile Testing Machine 150℃ With Chamber

Purpose of equipment :

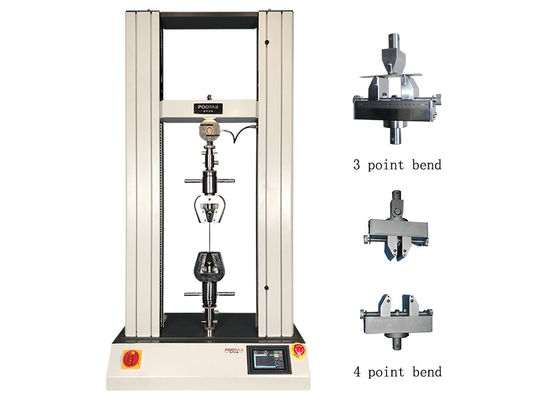

High and low temperature tensile testing machine is mainly suitable for testing metal and non-metal materials, such as rubber, plastic, wire and cable, fiber optic cable, safety belt, safety belt, leather belt composite material, plastic profile, waterproof coil, steel pipe, copper, Profiles, spring steel, bearing steel, stainless steel (and other high-hardness steels), castings, steel plates, steel strips, and non-ferrous metal wires have tensile, compression, bending, shearing, peeling, tearing, two points under high temperature environments Extension (extensometer is required) and many other tests.This high temperature UTM machine is integrating high and low temperature test box and tension testing machine.It is specially designed to simulate the physical performance testing of various materials under different environmental conditions.

Features :

The high and low temperature tensile testing machine adopts imported photoelectric encoder for displacement measurement, and the controller adopts embedded single-chip microcomputer structure, built-in powerful measurement and control software, integrating measurement, control, calculation, and storage functions. With automatic calculation of stress, elongation (extensometer required), tensile strength, modulus of elasticity, automatic statistical results; automatic recording of the maximum point, breaking point, specified point force value or elongation; use computer for testing Dynamic display of the process and test curve, and data processing. After the test, the curve can be enlarged and analyzed and edited by the graphic processing module, and the report can be printed.

Technical Parameters :

| Model Name |

PT-1167GDW High And Low Temperature Tensile Testing Machine 150℃ With Chamber |

| Load Cell Capacity |

200,500 ,1000,2000kgf, any one option

(2KN,5KN,10KN,20KN)

|

| Temperature Range |

-20℃,-40℃,-60℃~150℃ (200℃ customized)

(With observe window, lighting)

|

| Chamber Inner Size |

220*350*450mm

(or customized)

|

| Temperature Fluctuation |

±0.5℃ |

| Temperature Uniformity |

≤±2℃ |

| Heating Rate |

3℃/min (no load) |

| Cooling Rate |

0.7~1℃/min (no load) |

| Software |

Professional testing software under Windows |

| Force Measurement Accuracy |

±0.5% |

| Deformation Measurement Resolution |

0.01mm |

| Effective Force Range |

0.5~100%F.S |

| Deformation Indicates Value Accuracy |

±0.5% |

| Testing Speed |

0.05~1000mm/min |

| Test Travel |

Max 450mm,exclude grip/clamp |

| Effective Test Space |

Left right 220mm,front back 350mm |

| Unit switch |

a variety of internationally accepted units of measurement |

| Stop mode |

Upper and lower security settings, emergency stop button, the program setting of strength and elongation, specimen damage sensing. |

| Standard Configuration |

fixture/grip* 1 pair, machine seat*1, software and data line*1, power line*1, operation manual*1 qualification certificate*1, warranty card*1 |

| Size(W×D×H)cm |

Tensile machine 76×45×154,chamber 105×45×60,

Seat 80×60×71,after assembly 80×105×225

|

| Weight |

About 300kg |

| Motor |

Panasonic AC servo motor (Japan) |

| Power Supply |

1PH,AC220V,50/60Hz,15A (with a transformer to meet the customer's local national voltage and power requirements) |

Tensile Testing Machine With Chamber Pic :

Uiversal Tensile Tester With Chamber Inside :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!