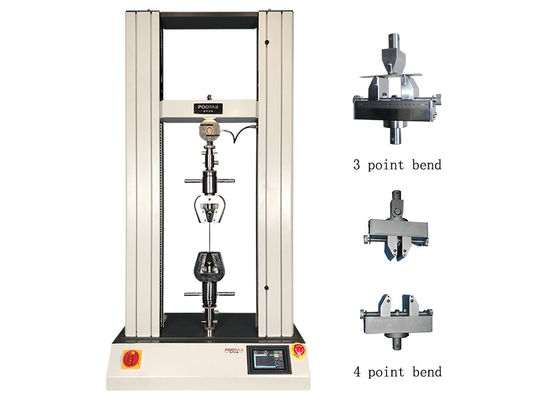

600KN Hydraulic Universal Testing Machine Tensile Compressive Bending Tester

600KN Hydraulic Universal Testing Machine Purpose:

Tensile Compressive Bending Tester is the use of fuel tank mounted under the host and mainly used for tensile, compression, bending and shear tests of metal or non-metallic materials, suitable for metallurgy, construction, light industry, aviation, aerospace, materials, universities, research institutes and other fields.Test operations and data processing meet GB228-2002 "metal materials at room temperature tensile test method" requirements.

600KN Testing Machine Description:

(1) Host:

Host is the use of the fuel tank mounted under the host, the tensile space located at between of the upper crossbeam and lower crossbeam, and the compression, bending, shears test space located at between of the lower crossbeam and a host base. The host structure show as below

(2) Transmission System

Lower crossbeam’s rising and falling is the use of the motor, cycloid reducer, chain gears, and lead screw nut drive, to adjust the space of tensile and compression.

(3) Hydraulic System (piano desktop oil source)

A. Hydraulic principles

As shown below is adaptive load oil into the throttle governing system.Hydraulic oil in the tank through the motor to drive high pressure gear pump into the oil passage, flow through the check valve, 10μ high pressure filter, pressure valve, servo valve, into the cylinder. Computer sends a control signal to the servo valve, control and direction of the opening of the servo valve to control the flow into the cylinder to achieve constant test force, constant displacement control.

B. Feature:

(a) High pressure gear pump, low noise, and smooth pressure.

(b) Dynamical Systems and operations console integrated design, easy to operate, and saving experiments space.

(c) Surface after spray treatment, appearance is beautiful.

600KN Universal Testing Machine Parameters:

| Machine Name |

600KN Hydraulic Universal Testing Machine Tensile Compressive Bending Tester |

| Model Number |

PT-1100-600 |

|

The Measuring Range of Test Force

|

12 kN to 600 kN

|

|

Test Force Display value Accuracy

|

± 1% |

|

Displacement Measurement Resolution

|

0.01mm

|

| Deformation Measurement Accuracy |

±0.5%

|

| Constant force, Constant deformation, Constant Displacement Control Range |

0.4% ~ 100% FS

|

|

Pistons Maximum Speed

|

100mm / min

|

| Maximum Tensile Test Space |

650mm (including the piston stroke) |

| Maximum Compression Space |

480mm (including the piston stroke).

|

|

Flat Specimen Clamping Thickness

|

0-15mm |

| Round Specimen Clamping Diameter |

Ø 13- Ø 26mm or Ø 26- Ø 40mm |

|

Pressure Plate Dimensions

|

Ø 120mm |

|

Bending Test Spacing

|

350 mm

|

|

Branch Roll Width

|

140 mm

|

|

Fulcrum Diameter

|

Ø 50 mm

|

| Piston Stroke |

250mm |

| Clamping Method |

Hydraulic clamping

|

| Sensor and Amplifier |

oil pressure sensor, plug in a PC programmable |

| Dimensions |

Host: 900×600×2250 mm

Oil Source: 1400×700×850 mm

|

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!