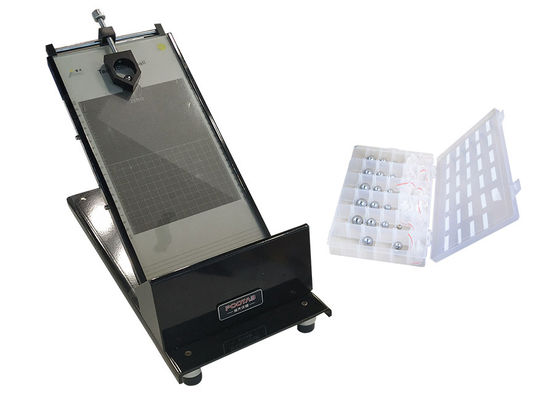

Operation Steps Of Roll Ball Tack Testing :

1. Place the machine on a stable table so that the pointer is aligned with the zero line of the Angle plate; Adjust the floor to level the work surface.

2. Then adjust the work surface to the Angle required by the test, generally 30°.

3. Fix the adhesive tape (test strip) to be tested on the working table (100 mm below the center of the ball is the running section), and fix the bottom edge of the test strip extending to the steel ball box with 500g weight, so that the test strip is naturally flat under a heavy weight.

S1. The test slice should be at least 4 pieces with a width (10 ~ 80 mm) and a length of about 250mm. If the elongation of the test slice is large, the test slice should be left for a period of time before the test.

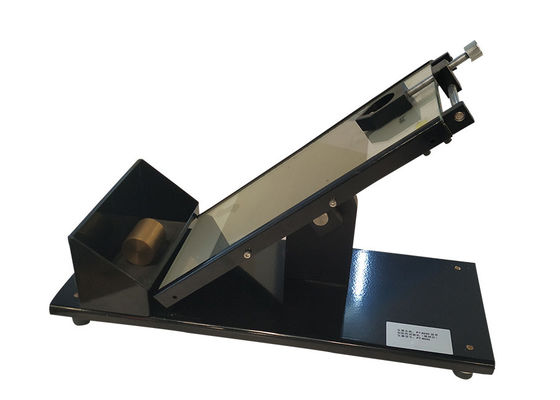

S2. For the run-up section, the transparent polyester film of electrical appliances with a thickness of 25 m and a length of more than 100 mm is pasted on the adhesive surface of > at the designated position of the test piece, with a length of 100 mm.

S3.100mm run-up is adjusted by adjusting the bolts on the machine and corresponding positions of the rolling balls with different ball sizes.

4. Pre-select maximum roll

Adjust the starting position of the ball, select balls with different ball Numbers, and repeat the systematic operation of ball cleaning and rolling.Pick the largest of the primary balls that are stopped in the measurement interval (the ball does not move for more than 5 seconds).Take the largest ball selected from the same test piece and the two balls with the ball number and its adjacent size, and test them on the same sample once each to confirm the ball with the largest ball number.(rolling the test on the same chip several times before picking the largest ball is acceptable, but it cannot be used as official test data.)

5. Formal testing

Take three samples and roll the ball on each of them with the maximum ball number selected.If a sample cannot stick the ball, the smaller ball can be used for a test. If it still cannot stick, the test shall be retested according to the steps of "pre-selected maximum ball" and "formal test".

6. Test results

The test results are expressed as the median ball number (ball diameter) of the ball test results of the three samples in the formal test.

Rollong Ball Tack Tester Photo :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!