BOPP Tape Adhesion Peel Strength Tester 90 Degree Angle Stripping JIS K6854

PT-6086S.pdf

Use :

this peel strength tester specifically for adhesive tape and adhesive industry design and development, suitable for a variety of adhesive products in different ways peeling strength testing of test equipment. Optional purchase different fixtures can be use for 180˚ peel, 90˚ peel, loop tack test,T-shaped and floating roller method (for high strength adhesive) peel test, mechanical adhesion, bonding strength,destructive test,lapjoint strength and other adhesive of tensile shear strength, splitting strength tests.

Applicable materials :

Cover tape,transparent tape,mask tape,double faced adhesive tape,fireproof tape,industrial tape,BOPP tape,adhesive sticker,adhesive label,label printing,PVC adhesive label,PET adhesive sticker,coated paper sticker,PE adhesive sticker,protective film,die cut,bonding adhesive tape,single sided adhesive tape,foam,paper liner,ployester liner,release liner,etc.

Part Of Meet Standards :

ASTM C273 – Standard Test Method for Shear Properties of Sandwich Core Materials

ASTM C633 – Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings

ASTM D897 – Standard Test Method for Tensile Properties of Adhesive Bonds

ASTM D903 – Peel or Stripping Strength of Adhesive Bonds

ASTM D1002 – Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens

ASTM D1781 – Standard Test Method for Climbing Drum Peel for Adhesives

ASTM D1876 – Peel Resistance of Adhesives (T-Peel Test)

ASTM D6195 – Standard Test Methods for Loop Tack

ASTM D3167 – Floating Roller Peel Resistance of Adhesives

ASTM D3330 – Peel Adhesion of Pressure-Sensitive Adhesives

ASTM D3759 – Tensile Strength and Elongation of Pressure-Sensitive Tapes

90 Degree Peel Strength Tester Parameter :

| Model |

PT-6086S BOPP Tape Adhesion Peel Strength Tester 90 / 180 Degree Angle Stripping JIS K6854 |

| Sensor Capacity |

2,5,10,20,50,100kg any one option |

| Measurement and Control Software |

CI701G |

| Measurement Accuracy |

±0.5% |

| Force Resolution |

1/500,000 |

| Effective Range of Measurement |

0.5~100%F.S |

| Deformation Display Accuracy |

±0.5% |

| Test Speed |

0.1~1000mm/min |

| Max Test Stroke |

Max 650mm,not included gripper |

| Effective Test Space |

Dia 120mm |

| Unit Switch |

A variety of measurement units including international units |

| Stop Method |

Upper and lower limit safety setting, emergency stop button, program strength and elongation setting, test piece failure |

| Special Function |

The holding, holding and fatigue testing can be done |

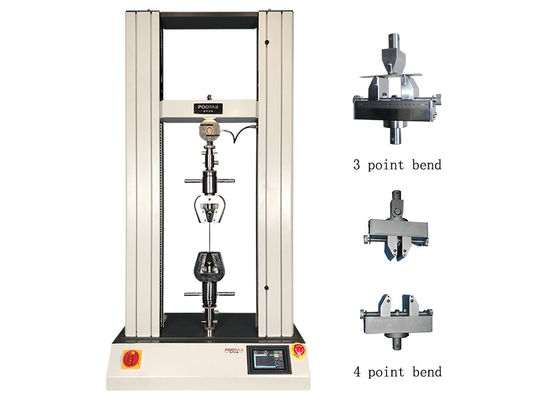

| Standard Configuration |

90° peel fixture 1 set , 3 pieces peel steel plates (50*150mm),PT-6020 manual rolling wheel 1 piece, software and RS232 data line 1 sets, 1 sets of equipment power supply, CD 1 CD-ROM operating instructions, product certification 1 copies, 1 copies of product warranty card |

| Purchase Configuration |

customer can choose to buy 180° peel fixture ,loop tack fixture, business computer , color printer , and other test fixtures |

| Machine Size |

About 57×47×120cm(W×D×H) |

| Machine Weight |

About 70kg |

| Motor |

AC Servo Motor |

| Control Method |

Touch Screen & Computerized |

| Power |

1PH,AC220V,50Hz,10A or as specified |

90° Peel Machine Picture :

90 Degree Peel Test Details Photo:

peel steel plate cleaning

specimen rolling on stianless steel plate

90 degree peel with tensile testing machine

Peel Strength Testing Result :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!