Metal Materials Universal Testing Machine , Tensile Compression Bending Testing Equipment 300KN

Technical Parameters :

1. Max Test Foce: 300 KN (30Tons)

2. Machine Grade: 1 Class

3. Effective Measure Range: 2%-100%FS

4. Indication Relative Error: ±1%

5. Force Resolution: 1/500000

6. Stress Rate Control Adjustment Range: 1MPa/s~~60MPa/s

7. Stress Rate Control Accuracy: ±2%

8. Deformation Resolution: 1/500000

9. Strain Rate Control Adjustment Range: 0.00025/s~~0.0025/s

10. Strain Rate Control Accuracy: ±2%

11. Displacement Resolution: 0.001

12. Displacement Rate Control Adjustment Range: 0.00025/s~~0.0025/s

13. Displacement Rate Control Accuracy: ±1%

14. Sress/Strain/Displacement Control Range: 0.3%~~100%FS

15. Stress/Strain/Displacement Control Accuracy: ±1%

16. Tensile Space: 600mm

17. Compress Space: 500mm

18. Columns Distance: 450mm

19. Round Sample Clamp Range: Φ6-Φ26mm

20. Flat Sample Clamp Thickness: 0-30mm

21. Flat Sample Clamp Width: 75mm

22. Compress Plate: Φ160mm

23. Machine Size: About 740*590*2100mm

24. Oil Source Console Dimensions: About 1150*800*1000mm

25.Total Motor Power: 2KW

26. Weight: About 2000kg

Functions and applicable testing methods:

Mainly used for tensile test of metal materials.With the addition of accessories, compression, bending, shear and other mechanical properties can be completed.

1. Meet GB/T228, 1-2010 "tensile test method for metallic materials at room temperature".

2 .Meets ISO 6892-1:2009 tensile test for metallic materials -- part 1: test methods at room temperature

Structural Design :

Tensile and compress two test Spaces.Compression space between test table and lower beam.Stretch space between upper and lower beams.The screw rotates to drive the lower beam up and down, which can complete the adjustment of test space.

Configuration List :

1. Machine Host: Under cylinder type, four columns and two screws, base integral casting.

2. Load Cell: 300KN

3. Compress Plate: Φ160mm

4. Hydraulic pressure source

5. Servo pump unit

6. Software testing system

7. Displacement sensor, pull wire photoelectric encoder

8. Computer: Lenovo

9. User manual, qualified certificate, packing list

10.Clamping action: hydraulic tightened

11.Defend the net

12.Round specimen tensile clamp: Φ6 - Φ13mm, Φ13 - Φ26mm

13.Flat specimen tensile clamp: 0-15mm

Core configurations and functions :

1. Sensor -- force measurement

2. Electronic extensometer -- deformation measurement within the range of standard distance

3. Photoelectric encoder -- measurement of displacement value

4. Servo system -- application of test force and control of test rate (patented technology)

5. Software -- data collection and processing

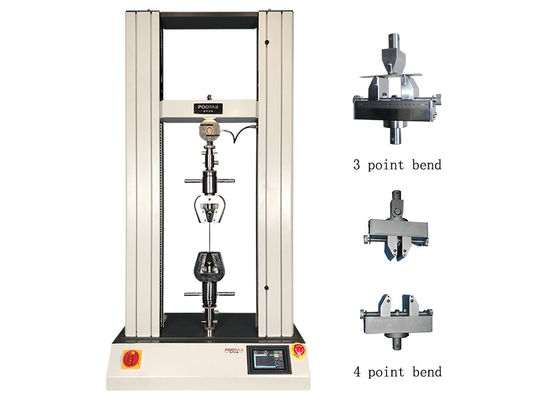

30T Universal Tesing Pictures:

Accessories Grip :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!