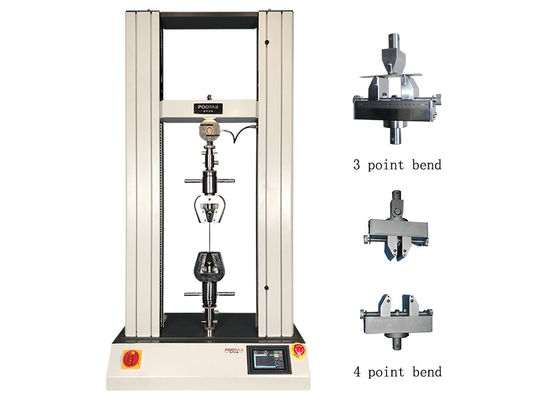

300KN Universal Testing Machine Metal Cable Rope Tube Tensile Strength Test

Use Introduction :

The 30 ton hydraulic servo universal material testing machine is mainly used for polishing round steel bars, ribbed steel bars, straight steel bars, coiled steel bars, metal plates, metal bars, cables and ropes, castings, forgings, bolt fasteners, metal pipes Such as metallic materials and non-metallic materials are subjected to tensile tests, compression tests, bending tests, shear tests and other mechanical tests at room temperature.This 300KN UTM machine is equipped with a computer, printer, electronic extensometer, photoelectric encoder, and testing software, which can accurately determine the tensile strength, yield strength, specified proportional extension strength, elongation, elastic modulus, etc. of metal materials.

Detailed Parameters :

| Model Name |

PT-1100-300 Universal Testing Machine Metal Cable Rope Tube Tensile Strength Test 300KN |

| Max Test Force |

300 KN |

|

Force Measure Grade

|

1 Class |

| Effective Measure Range |

2%-100%FS

(6KN-300KN)

|

| Indication Relative Error |

±1% |

| Force Resolution |

1/500000 |

| Stress Rate Control Adjustment Range |

1MPa/s~~60MPa/s |

| Stress Rate Control Accuracy |

±2% |

| Deformation Resolution |

1/500000 |

| Strain Rate Control Adjustment Range |

0.00025/s~~0.0025/s |

| Strain Rate Control Accuracy |

±2% |

| Displacement Resolution |

0.001 |

| Displacement Rate Control Adjustment Range |

0.00025/s~~0.0025/s |

| Displacement Rate Control Accuracy |

±1% |

| Stress/Strain/Displacement Control Range |

0.3%~~100%FS |

| Stress/Strain/Displacement Control Accuracy |

±1% |

| Tensile Space |

600mm |

| Compress Space |

500mm |

| Columns Distance |

450mm |

| Round Sample Clamp Range |

Φ6-Φ26mm |

| Flat Sample Clamp Thickness |

0-30mm |

| Flat Sample Clamp Width |

75mm |

| Compress Plate |

Φ160mm |

| Machine Size |

About 740*590*2100mm |

| Oil Source Console dimensions |

About 1150*800*1000mm |

| Total Motor Power |

2KW |

| Machine Weight |

About 2000kg |

300KN UTM Machine Structure :

The main engine has two uprights, two lead screws, and a lower cylinder. The tensile space is located above the main engine, and the compression and bending test space is located between the lower beam of the main engine and the workbench. The data measurement and control system uses high-precision A/D converters to collect data on force, displacement, and deformation. It has the characteristics of high measurement accuracy and good reliability. It meets GB, ISO, ASTM and other standards. For metal stretching, compression, and bending , Shear and other test requirements.

Transmission System :

The lifting and lowering of the lower crossbeam adopts a motor driven by a reducer, a chain transmission mechanism, and a screw pair to realize the adjustment of the tension and compression space.

Hydraulic System :

The hydraulic oil in the oil tank is driven by the motor to drive the high-pressure pump into the oil circuit, flows through the high-pressure oil filter, returns to the oil valve, and enters the oil cylinder. The computer collects and analyzes the data through the sensor and displays the time-to-time value. The tester controls the flow through the oil delivery valve to realize the speed of the test force.

Control System :

- Support for tensile, compression, shear, bending and other tests;

- Manually adjust the oil return valve, the operation is simple and flexible;

- Support customization of test parameters;

- Use open EXCEL report form, support user-defined report format;

- Query and print test results are flexible and convenient, support printing multiple samples, custom sorting and printing items;

- The program comes with powerful test analysis functions;

- The program supports hierarchical management of two levels (administrator, tester) user management authority;

Refer picture of 300KN Universal Testing Machine :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!