Product Description:

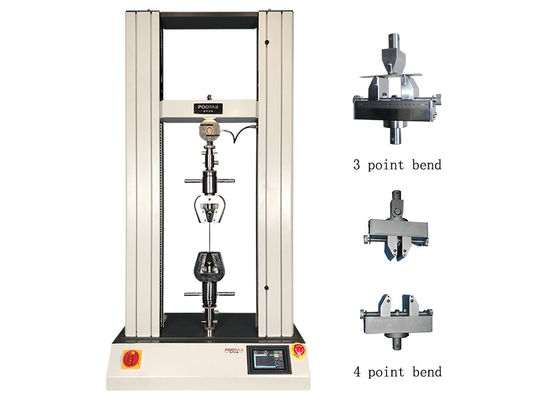

The Universal Testing Machine is a state-of-the-art device designed to perform a wide range of material testing applications with exceptional precision and reliability. As a versatile Universal Strength Tester, it is engineered to meet the stringent demands of modern industrial and research environments, ensuring accurate measurement of mechanical properties such as tensile strength, compressive strength, and elongation. This machine is also recognized as a Universal Hardness Tester, capable of conducting hardness tests on various materials with consistent and repeatable results, making it an indispensable tool for quality control and material analysis.

One of the standout features of this Universal Testing Machine is its integration of a high-precision CCD Industrial Camera. This advanced camera system enhances the testing process by capturing detailed images of the specimen during testing. The high resolution and clarity provided by the CCD camera enable precise monitoring of deformation, crack propagation, and other critical phenomena in real-time. This visual data is invaluable for in-depth analysis and helps engineers and researchers gain a comprehensive understanding of material behavior under different loading conditions.

Complementing the industrial camera is the machine's Dedicated Image Analysis Software, which is specifically designed to work seamlessly with the captured images. This software allows for sophisticated image processing, measurement, and evaluation, facilitating a thorough examination of the test results. Users can easily analyze the deformation patterns, calculate strain distributions, and identify failure points with high accuracy. The integration of this specialized software ensures that the Universal Hardness Tester provides not only mechanical data but also rich visual insights, thereby enhancing the overall testing capability.

The Universal Testing Machine is equipped with Professional Testing Software developed by BaoDa, tailored to run on the Windows platform. This measurement software is designed to provide an intuitive user interface, extensive functionality, and robust data management features. It supports a wide range of testing standards and protocols, making it adaptable to various industry requirements. The software enables users to set up tests, control testing parameters, and collect data efficiently. Moreover, it offers comprehensive reporting tools that help in documenting and analyzing test results effectively, streamlining the workflow for engineers and technicians alike.

Flexibility in measurement units is another key attribute of this Universal Strength Tester. The machine supports multiple measurement units, including international units, which facilitates global usability and compliance with international testing standards. Users can easily switch between units such as Newtons, kilograms-force, pounds-force, and others, depending on their specific needs or regional standards. This unit switching capability ensures that the testing data is easily interpretable and compatible with various quality assurance and certification processes worldwide.

In addition to its testing capabilities, the Universal Testing Machine features a controlled heating rate of 3°C per minute under no load conditions. This precise heating rate allows for thermal testing and conditioning of samples in a controlled environment, which is critical for materials that exhibit temperature-dependent properties. The ability to apply uniform heating at a steady rate ensures that thermal effects on material strength and hardness can be accurately assessed, broadening the scope of applications for this Universal Hardness Tester.

In summary, the Universal Testing Machine is a comprehensive solution for material testing, combining advanced hardware and software technologies to deliver precise, reliable, and versatile performance. As both a Universal Strength Tester and a Universal Hardness Tester, it caters to a wide array of testing needs, supported by a high-precision CCD Industrial Camera, Dedicated Image Analysis Software, and Professional Testing Software developed by BaoDa. Its multiple measurement units and controlled heating rate further enhance its functionality, making it an essential instrument for industries and laboratories focused on material quality and performance evaluation.

Features:

-

Product Name: Universal Testing Machine

-

Also known as Universal Hardness Tester, Universal Strength Tester, and Universal Tensile Tester

-

Cooling Rate: 0.7 To 1°C/min (no Load)

-

Standard Configuration:

-

Special Rubber Fixtures 1 Set

-

Software And Data Cable 1 Set

-

Equipment Power Cord 1

-

CCD Industrial Camera 1

-

High-precision Camera 1

-

Operation Manual 1

-

Product Certificate 1

-

Product Warranty Card 1

-

Machine Size/Weight: Approximately 100×50×65cm (W×D×H) / Approximately 70kg

-

Input Ports:

-

Load Cell Input

-

CCD Industrial Camera Interface

-

Analysis Software Interface

-

Optional Configuration:

-

Commercial Computer

-

Printer 1

Technical Parameters:

|

Cooling Rate

|

0.7 To 1°C/min (no Load)

|

|

Temperature Fluctuation

|

±0.5°C

|

|

Heating Rate

|

3°C/min (no Load)

|

|

Unit Switching

|

Multiple Measurement Units Including International Units

|

|

Measurement Software

|

Professional Testing Software Developed By BaoDa On Windows Platform

|

|

Optional Configuration

|

Commercial Computer, Printer 1

|

|

Input Ports

|

Load Cell Input, CCD Industrial Camera Interface, Analysis Software Interface

|

|

Control Method

|

Computer Control System

|

|

Industrial Camera

|

High-precision CCD Industrial Camera

|

|

Maximum Stroke

|

Up To 100mm, Including Fixtures

|

This Universal Strength Tester, also known as a Universal Tensile Tester and Universal Hardness Tester, offers precise control and versatile measurement capabilities suitable for various testing applications.

Applications:

The Pootab Universal Testing Machine, originating from Guangdong, is an advanced and versatile device designed for a wide range of testing applications in various industries. This Universal Tensile Tester is perfectly suited for measuring the tensile strength, compression strength, and other mechanical properties of materials with high precision. Its robust construction, approximately 100×50×65cm in size and weighing around 70kg, ensures stable and reliable performance in both laboratory and industrial environments.

This Universal Hardness Tester is equipped with a high-precision CCD industrial camera and a special rubber fixture set, enabling accurate and repeatable measurements of material hardness. The inclusion of a high-precision camera enhances the machine’s capability to capture detailed images during testing, facilitating better analysis and documentation. Additionally, the professional testing software developed by BaoDa on the Windows platform provides comprehensive data acquisition, real-time monitoring, and multiple measurement unit options, including international units, to cater to diverse testing requirements.

The Universal Tensile Tester from Pootab is ideal for use in quality control laboratories, research and development centers, educational institutions, and manufacturing plants. It is particularly useful for testing metals, plastics, rubber, textiles, and composites, making it indispensable for industries such as automotive, aerospace, electronics, and construction. The machine’s standard configuration includes software and data cables, an equipment power cord, an operation manual, a product certificate, and a product warranty card, ensuring users have everything necessary for immediate and effective use.

In terms of application scenarios, this Universal Testing Machine is perfect for tensile testing of wires and cables, hardness testing of plastic components, compression testing of rubber materials, and many other mechanical property evaluations. Its precise unit switching capability allows technicians and engineers to easily switch between different measurement units, facilitating international collaboration and compliance with global standards. The integration of industrial-grade cameras also supports detailed visual inspection during tests, which is critical for failure analysis and quality assurance.

Overall, the Pootab Universal Tensile Tester and Universal Hardness Tester offer a comprehensive solution for material testing needs, combining high accuracy, ease of use, and versatile functionality. Whether used in production lines or research labs, this machine delivers dependable results and supports enhanced material performance evaluation, making it a valuable investment for any organization focused on quality and innovation.

Customization:

The Pootab Universal Strength Tester, originating from Guangdong, offers exceptional customization services tailored to meet diverse testing needs. This Universal Strength Tester features precise temperature uniformity of ≤±2°C, ensuring reliable and consistent testing conditions.

Equipped with multiple input ports including Load Cell Input, CCD Industrial Camera Interface, and Analysis Software Interface, the Universal Strength Tester allows seamless integration with various measurement and analysis tools. The standard configuration includes a complete set of special rubber fixtures, professional testing software developed by BaoDa on the Windows platform, data and power cables, a high-precision CCD industrial camera, operation manual, product certificate, and warranty card.

With a controlled cooling rate of 0.7 to 1°C/min (no load), the Universal Strength Tester ensures precise thermal management during testing procedures. Its professional measurement software provides advanced testing capabilities and user-friendly operation, making the Pootab Universal Strength Tester a reliable and versatile choice for material strength evaluation.

Support and Services:

Our Universal Testing Machine is backed by comprehensive technical support and services to ensure optimal performance and longevity. Our team of experienced engineers and technicians are available to assist with installation, calibration, maintenance, and troubleshooting. We provide detailed user manuals and training sessions to help you maximize the capabilities of your testing machine.

Regular maintenance services are offered to keep your equipment running smoothly and to prevent unexpected downtime. Calibration services ensure that your machine meets industry standards and provides accurate and reliable test results.

In case of any technical issues, our support team is ready to provide prompt assistance through remote diagnostics and on-site service visits when necessary. We also offer software updates and upgrades to enhance functionality and keep your testing processes up to date.

Whether you need guidance on selecting the right accessories and fixtures or require customized solutions for specific testing requirements, our customer support is committed to helping you achieve precise and consistent results with your Universal Testing Machine.

Packing and Shipping:

The Universal Testing Machine is carefully packaged to ensure safe delivery and optimal protection during transit. The machine is first wrapped in protective foam padding to prevent any damage from shocks or vibrations. It is then placed inside a sturdy, custom-designed wooden crate that provides structural support and resistance against external impacts.

Additional cushioning materials such as bubble wrap and foam inserts are used to secure delicate components and accessories within the crate. All loose parts and accessories are individually packed and clearly labeled to facilitate easy identification and assembly upon arrival.

The packaging is sealed securely and marked with handling instructions, including “Fragile” and “This Side Up” labels, to guide carriers during transportation. The crate is also equipped with forklift slots for safe and efficient handling.

For shipping, we partner with reliable logistics providers to ensure timely and safe delivery to the customer’s location. Shipping options include standard freight, expedited delivery, and international shipping with full tracking and insurance coverage.

Upon receipt, customers are advised to carefully inspect the packaging for any signs of damage and report any issues immediately. Our customer support team is available to assist with installation, setup, and any post-delivery concerns to ensure a smooth experience with the Universal Testing Machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!