Product Description:

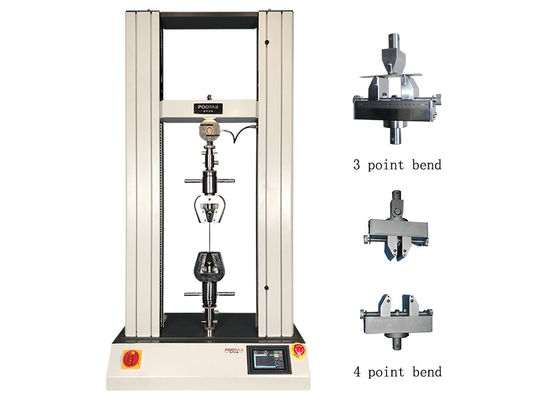

The Universal Testing Machine, also known as the Universal Strength Tester or Universal Tensile Tester, is a state-of-the-art device designed to perform a wide range of mechanical tests on materials and components. This versatile machine is essential for quality control, research, and development across various industries such as manufacturing, construction, aerospace, and automotive. It provides precise and reliable measurements of tensile strength, compressive strength, elongation, and other critical material properties, ensuring that products meet stringent industry standards and specifications.

One of the standout features of this Universal Strength Tester is its advanced input ports, which enhance its functionality and ease of use. The machine is equipped with a Load Cell Input that accurately measures the applied force during testing, ensuring high precision and repeatability. Additionally, it includes a CCD Industrial Camera Interface, allowing for real-time visual monitoring and recording of the specimen during testing. This feature is particularly useful for analyzing deformation and failure patterns. Furthermore, the Universal Testing Machine supports an Analysis Software Interface, enabling seamless integration with specialized software for comprehensive data analysis, reporting, and documentation.

The optical system of this Universal Tensile Tester is enhanced by a high-resolution industrial lens. This industrial lens provides exceptional clarity and detail, facilitating accurate observation and measurement of specimen behavior under stress. The high-resolution lens is crucial for applications that require detailed visual inspection, such as microstructural analysis and crack propagation studies, making the machine highly suitable for both standard and advanced testing scenarios.

The Universal Testing Machine offers multiple capacity options to accommodate various testing requirements. Users can select from 5, 10, 20, and 50 Kgf capacity models, ensuring flexibility and adaptability for different materials and test scales. Whether testing delicate materials with low force requirements or robust specimens needing higher capacity, this machine delivers consistent performance and reliability across all options. This range of capacities makes the machine an ideal choice for laboratories and production environments with diverse testing needs.

Powering the Universal Strength Tester is a high-efficiency AC servo motor, which guarantees smooth, accurate, and controllable motion throughout the testing process. The servo motor allows for precise control of test speed and force application, enhancing the machine's overall performance and accuracy. This power system also contributes to the machine’s durability and energy efficiency, making it a cost-effective solution for long-term use.

Safety is a paramount consideration in the design of this Universal Tensile Tester. The machine incorporates multiple shutdown methods to protect both the operator and the specimen. It features left and right limit safety settings that automatically stop the machine when the testing limits are reached, preventing over-travel and potential damage. An emergency stop button is also included, allowing immediate cessation of operation in case of any unexpected issues. Additionally, the machine is equipped with specimen destruction detection, which halts the test as soon as the material fails, ensuring accurate data collection and preventing unnecessary strain on the equipment.

In summary, the Universal Testing Machine is a highly versatile, precise, and safe Universal Strength Tester that meets the rigorous demands of modern material testing. With its advanced input ports, high-resolution industrial lens, multiple capacity options, powerful AC servo motor, and comprehensive safety features, it stands out as an indispensable tool for engineers, researchers, and quality control professionals. Whether used for tensile, compressive, or other mechanical tests, this Universal Tensile Tester delivers reliable results that drive innovation and quality assurance in various industries.

Features:

-

Product Name: Universal Testing Machine, also known as Universal Strength Tester and Universal Tensile Tester

-

Temperature Control Range: -20°C to 100°C, equipped with window and lighting for clear observation

-

Shutdown Method: Includes left and right limit safety settings, emergency stop button, and specimen destruction detection for enhanced safety

-

Force Accuracy: Better than ±0.5%, meeting GB-0.5 level standards

-

Capacity Options: Available in 5, 10, 20, and 50 Kgf to suit various testing needs

-

Temperature Uniformity: Maintains temperature uniformity within ≤±2°C for consistent test results

Technical Parameters:

|

Force Accuracy

|

Better Than ±0.5% (GB-0.5 Level)

|

|

Unit Switching

|

Multiple Measurement Units Including International Units

|

|

Power

|

AC Servo Motor

|

|

Temperature Control Range

|

-20°C To 100°C (with Window And Lighting)

|

|

Industrial Camera

|

High-precision CCD Industrial Camera

|

|

Input Ports

|

Load Cell Input, CCD Industrial Camera Interface, Analysis Software Interface

|

|

Cooling Rate

|

0.7 To 1°C/min (no Load)

|

|

Machine Size/Weight

|

Approximately 100×50×65cm (W×D×H) / Approximately 70kg

|

|

Temperature Uniformity

|

≤±2°C

|

|

Heating Rate

|

3°C/min (no Load)

|

Applications:

The Pootab Universal Testing Machine, originating from Guangdong, is an advanced piece of equipment designed to meet diverse testing needs in various industrial and research environments. This Universal Tensile Tester is widely used for assessing the mechanical properties of materials, including tensile strength, compression strength, and hardness, making it an indispensable tool in quality control laboratories, manufacturing plants, and academic research institutions.

One of the primary application occasions for the Pootab Universal Tensile Tester is in material testing laboratories where precise measurement of material properties is critical. The machine’s professional testing software, developed by BaoDa on the Windows platform, ensures accurate data acquisition and analysis, catering to the rigorous demands of engineers and researchers. Its high-resolution industrial lens and high-precision camera enable detailed observation and recording of specimen behavior during testing, which is essential for failure analysis and material characterization.

In manufacturing industries, the Universal Hardness Tester functionality integrated into this machine allows for efficient hardness testing of metals, plastics, and composites, ensuring that products meet industry standards and customer specifications. The device’s standard configuration includes special rubber fixtures, a CCD industrial camera, and necessary cables, making it ready for immediate use in production lines and quality assurance departments.

Safety and reliability are paramount during testing procedures. The Pootab Universal Testing Machine incorporates advanced shutdown methods such as left and right limit safety settings, an emergency stop button, and specimen destruction detection, ensuring operator safety and preventing equipment damage during unforeseen events. These features make it suitable for high-stakes testing scenarios in automotive, aerospace, and construction material testing, where precision and safety cannot be compromised.

The machine’s versatile input ports, including load cell input, CCD industrial camera interface, and analysis software interface, allow seamless integration with various sensors and external devices, enhancing its adaptability to different testing scenarios. Researchers and technicians can utilize these features to customize testing protocols, collect comprehensive data, and perform in-depth analysis effectively.

Overall, the Pootab Universal Tensile Tester and Universal Hardness Tester excel in multiple application scenarios ranging from academic research, industrial manufacturing, product development, to quality assurance. Its robust design, cutting-edge software, and extensive safety features make it a preferred choice for professionals seeking reliable and precise material testing solutions.

Customization:

Pootab offers comprehensive product customization services for our Universal Testing Machine, designed to meet diverse testing needs. Manufactured in Guangdong, our Universal Hardness Tester and Universal Strength Tester come with multiple capacity options including 5, 10, 20, and 50Kgf, ensuring precise performance for various applications.

Equipped with a state-of-the-art Computer Control System, the Universal Strength Tester guarantees accurate and efficient operation. The machine integrates professional testing software developed by BaoDa on the Windows platform, providing user-friendly interfaces and reliable measurement results.

The Universal Testing Machine features a compact design with dimensions approximately 100×50×65cm (W×D×H) and a weight of around 70kg, making it suitable for various laboratory environments. Additionally, it maintains temperature fluctuation within ±0.5°C to ensure consistent and dependable testing conditions.

Whether you require a Universal Hardness Tester or a Universal Strength Tester, Pootab’s customization services ensure that each machine is tailored to your specific requirements, enhancing testing accuracy and operational efficiency.

Support and Services:

Our Universal Testing Machine is backed by comprehensive Product Technical Support and Services to ensure optimal performance and longevity. We provide expert guidance on installation, operation, and maintenance to help you achieve precise and reliable test results.

Our technical support team is available to assist with troubleshooting, calibration, and software updates. We offer routine maintenance services and calibration checks to keep your equipment functioning at peak accuracy.

Additionally, we provide training sessions and detailed user manuals to help operators understand the full capabilities of the machine and adhere to safety standards. Spare parts and accessories are readily available to minimize downtime.

Our commitment is to deliver exceptional service and support, enabling you to maximize the value and efficiency of your Universal Testing Machine throughout its service life.

Packing and Shipping:

The Universal Testing Machine is carefully packaged to ensure safe delivery and maintain product integrity during transit. The machine is securely placed in a custom-fitted foam mold inside a sturdy, double-walled corrugated cardboard box. All movable parts are immobilized to prevent damage, and sensitive components are wrapped with protective materials.

For added protection, the packaging includes moisture-resistant liners and desiccant packets to guard against humidity. The external box is clearly labeled with handling instructions such as "Fragile," "This Side Up," and "Handle with Care" to inform shipping personnel.

Shipping is carried out using reliable freight services that specialize in handling delicate industrial equipment. The Universal Testing Machine can be shipped via air, sea, or road freight depending on customer preference and destination. Tracking information and estimated delivery dates are provided to ensure transparency throughout the shipping process.

Upon receipt, it is recommended that the customer inspects the packaging for any signs of damage before accepting delivery and follows the included unpacking instructions to safely remove and set up the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!