Product Description:

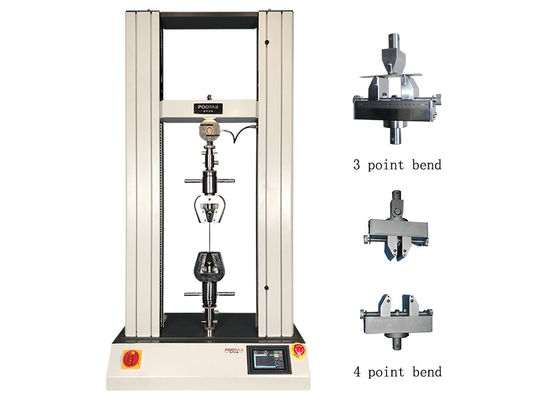

The Universal Testing Machine is a state-of-the-art Universal Strength Tester designed to meet the rigorous demands of modern materials testing. Engineered for precision and reliability, this versatile Universal Hardness Tester integrates advanced technology to deliver accurate and consistent results across a wide range of testing applications. Whether used in research, quality control, or production environments, this Universal Hardness Tester ensures that materials meet the required strength and hardness standards with utmost confidence.

One of the standout features of this Universal Strength Tester is its comprehensive input ports, which include a Load Cell Input, a CCD Industrial Camera Interface, and an Analysis Software Interface. The Load Cell Input allows for precise measurement of force applied during testing, ensuring that data collected is both reliable and repeatable. The CCD Industrial Camera Interface connects a high-precision CCD Industrial Camera, enabling visual monitoring and detailed inspection of specimens throughout the testing process. Additionally, the Analysis Software Interface facilitates seamless integration with professional testing software, allowing for sophisticated data analysis and reporting.

The heating system of this Universal Testing Machine is meticulously calibrated with a heating rate of 3°C per minute when operating under no load conditions. This controlled heating rate ensures that specimens are tested under consistent thermal conditions, eliminating variables that could affect the accuracy of hardness and strength measurements. This feature is particularly important for materials that are sensitive to temperature changes, providing users with dependable thermal control during testing procedures.

At the core of the machine’s data acquisition and control is the professional testing software developed by BaoDa, specifically designed for the Windows platform. This software offers an intuitive user interface that simplifies test setup, execution, and result analysis. Users can customize test parameters, monitor real-time data, and generate comprehensive reports that are essential for documentation and quality assurance. The BaoDa-developed measurement software enhances the overall functionality of the Universal Strength Tester, making it an indispensable tool for laboratories and industrial applications alike.

The inclusion of a high-precision CCD Industrial Camera elevates this Universal Hardness Tester to a new level of capability. The camera provides clear, detailed imaging of the specimen, allowing operators to observe crack propagation, deformation, and other critical phenomena during testing. This visual feedback complements the numerical data collected, offering a comprehensive understanding of material behavior under stress.

Safety and operational reliability are paramount in the design of this Universal Testing Machine. It incorporates multiple shutdown methods to protect both the operator and the specimen. These include left and right limit safety settings that automatically halt the machine when predefined boundaries are reached. An emergency stop button is readily accessible to immediately cease operation in case of unforeseen events. Furthermore, the system features specimen destruction detection, which automatically identifies when a specimen has failed, triggering an immediate shutdown to prevent further damage or hazards. These safety mechanisms ensure that the Universal Hardness Tester operates within secure parameters, fostering a safe working environment.

In summary, this Universal Testing Machine serves as a comprehensive Universal Hardness Tester and Universal Strength Tester, combining precision engineering, advanced software, and robust safety features. Its versatile input ports, controlled heating rate, professional software integration, and high-precision industrial camera make it an ideal solution for diverse materials testing needs. Whether assessing hardness, tensile strength, or other mechanical properties, this machine stands out as a reliable and efficient instrument that enhances testing accuracy and operational safety. For industries and laboratories seeking a dependable Universal Strength Tester, this product represents a superior choice that meets and exceeds contemporary testing standards.

Features:

-

Product Name: Universal Testing Machine

-

Also known as Universal Hardness Tester, Universal Strength Tester, and Universal Tensile Tester

-

Cooling Rate: 0.7 To 1°C/min (no Load)

-

Heating Rate: 3°C/min (no Load)

-

Temperature Uniformity: ≤±2°C

-

Maximum Stroke: Up To 100mm, Including Fixtures

-

Temperature Fluctuation: ±0.5°C

Technical Parameters:

|

Temperature Fluctuation

|

±0.5°C

|

|

Unit Switching

|

Multiple Measurement Units Including International Units

|

|

Capacity Options

|

5, 10, 20, 50 Kgf

|

|

Standard Configuration

|

Special Rubber Fixtures 1 Set, Software and Data Cable 1 Set, Equipment Power Cord 1, CCD Industrial Camera 1, High-precision Camera 1, Operation Manual 1, Product Certificate 1, Product Warranty Card 1

|

|

Optional Configuration

|

Commercial Computer, Printer 1

|

|

Input Ports

|

Load Cell Input, CCD Industrial Camera Interface, Analysis Software Interface

|

|

Industrial Camera

|

High-precision CCD Industrial Camera

|

|

Measurement Software

|

Professional Testing Software Developed By BaoDa On Windows Platform

|

|

Cooling Rate

|

0.7 To 1°C/min (no Load)

|

|

Power

|

AC Servo Motor

|

This Universal Strength Tester, also known as Universal Tensile Tester and Universal Hardness Tester, is designed for precise measurement and testing with advanced features and configurations.

Applications:

The Pootab Universal Tensile Tester, originating from Guangdong, is an essential instrument designed for a wide range of product application occasions and scenarios. Its versatility makes it ideal for use in industrial, academic, and research laboratories where precise material testing is required. Whether testing metals, plastics, textiles, or composites, the Universal Tensile Tester ensures accurate and reliable results, making it indispensable for quality control and material characterization.

In manufacturing environments, the Universal Tensile Tester plays a critical role in ensuring that materials and components meet stringent industry standards. The machine’s ability to maintain temperature fluctuation within ±0.5°C guarantees consistent testing conditions, which is crucial for materials sensitive to thermal variations. This precision supports applications such as tensile strength testing, compression testing, and flexural testing, allowing manufacturers to optimize product performance and durability before market release.

Research and development laboratories benefit greatly from the Pootab Universal Tensile Tester’s advanced features, including multiple measurement unit switching that supports international units. This feature is particularly useful for global collaborations and comparative studies, enabling seamless data interpretation across different regions and standards. Additionally, the heating rate of 3°C/min (no load) allows controlled thermal testing, expanding the range of material behavior analysis under varying temperatures.

The Universal Tensile Tester is also equipped with high-resolution industrial lenses, enhancing the visual inspection and analysis of specimens during testing. This is complemented by multiple input ports such as load cell input, CCD industrial camera interface, and analysis software interface, which together facilitate comprehensive data acquisition and real-time monitoring. These capabilities make the Universal Tensile Tester a vital tool in both automated and manual testing scenarios, supporting detailed failure analysis and material research.

Overall, the Pootab Universal Tensile Tester is perfectly suited for diverse application occasions, including product development, quality assurance, academic research, and industrial testing. Its robust build, precise control, and advanced interfacing options provide a reliable solution for users seeking high accuracy and versatility in universal material testing.

Customization:

At Pootab, we offer customized product solutions for our Universal Strength Tester to meet your specific testing requirements. Manufactured in Guangdong, our Universal Tensile Tester features precise temperature control with a heating rate of 3°C/min (no load) and exceptional temperature uniformity of ≤±2°C, ensuring consistent and reliable test results.

Our Universal Tensile Tester supports a wide temperature control range from -20°C to 100°C, complete with a viewing window and lighting for easy observation during testing. Powered by an AC servo motor, the machine guarantees smooth and efficient operation with force accuracy better than ±0.5% (GB-0.5 level), providing dependable performance for your material testing needs.

We tailor each Universal Strength Tester to your specifications, ensuring optimal functionality and precision. Trust Pootab's expertise to deliver a Universal Tensile Tester that perfectly fits your quality assurance processes.

Support and Services:

Our Universal Testing Machine is backed by comprehensive technical support and services designed to ensure optimal performance and longevity of your equipment.

We offer expert installation and calibration services to guarantee accurate and reliable test results. Our team of trained technicians is available to assist with setup and provide training to your staff on proper operation and maintenance procedures.

Regular maintenance and inspection services are available to prevent downtime and extend the life of your testing machine. In case of any technical issues, our responsive troubleshooting support helps diagnose and resolve problems efficiently.

We also provide software updates and upgrades to keep your testing system current with the latest features and compliance standards.

For customized testing solutions and applications support, our experts collaborate closely with you to tailor the machine’s capabilities to meet your specific requirements.

With our dedicated technical support and services, you can maximize the productivity and accuracy of your Universal Testing Machine, ensuring reliable testing outcomes for your materials and products.

Packing and Shipping:

Our Universal Testing Machine is carefully packaged to ensure safe delivery and optimal protection during transit. The machine is securely placed in a custom-fitted foam insert within a sturdy wooden crate to prevent any movement or damage.

All components, including accessories and manuals, are individually wrapped and cushioned to avoid scratches or impacts.

The packaging materials are chosen to withstand rough handling and environmental factors during shipping.

For shipping, we use reliable freight services with tracking and insurance options to guarantee timely and secure delivery to your location.

Upon receipt, please inspect the package for any visible damage before signing the delivery receipt. In case of any issues, contact our customer support immediately for assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!